Many talk about SMEs lagging behind in terms of digitalization. In Uhingen, a typical representative of SMEs has built an intelligent platform solution on its own initiative that makes the digitally connected future a reality for mechanical engineering and offers the best prospects for global expansion. This earned it an award as a “lighthouse project for Industrie 4.0” in July 2021. An interview with the Managing Director of EWS Weigele, Matthias Weigele. (Allpoctures EWS)

Ulrich Sendler: Mr. Weigele, what gave you the idea to set up the Tool-Arena as a platform for the supply of machines for metal-cutting production?

Matthias Weigele: It was a lecture on digitalization from which I took away that the digital future of industry also lies in the horizontal. That in the future it will no longer be the individual manufacturer who talks to the individual customer, but that all industrial consumers will be able to put together their products simply, securely and better via platforms. As has long been the norm with the major e-commerce platforms for consumer goods.

Matthias Weigele: It was a lecture on digitalization from which I took away that the digital future of industry also lies in the horizontal. That in the future it will no longer be the individual manufacturer who talks to the individual customer, but that all industrial consumers will be able to put together their products simply, securely and better via platforms. As has long been the norm with the major e-commerce platforms for consumer goods.

What did that mean for you?

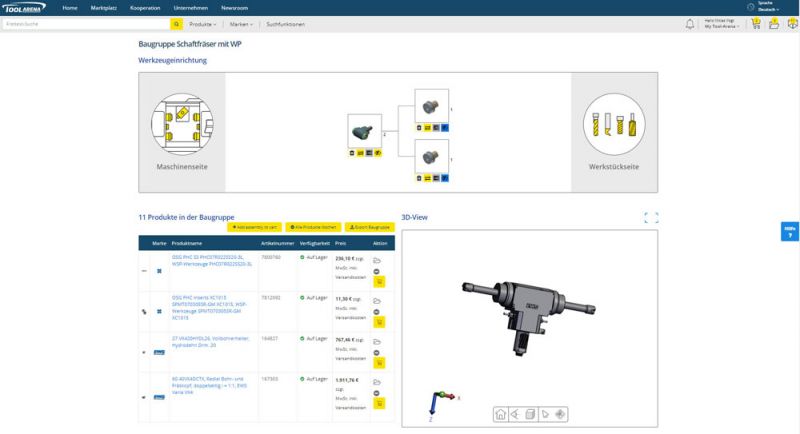

Weigele: We are a manufacturer of tool systems that are used on milling or turning-milling centers to hold cutting edge carriers. In addition to us, there are other companies, some in direct competition, and there is a wide range of other manufacturers whose products are also essential for any machine in metal-cutting manufacturing. Clamping devices, drives, cutting edges and many others. Today, the machine builder or his customer must gather these components from the various suppliers and then make sure each part fits and works. This is an huge effort, which we not only make obsolete with the Tool-Arena platform, but also supplement with an offer that could not exist without this platform.

What exactly does the Tool Arena offer?

Weigele: First, the customer only selects components here that are guaranteed to fit together, for example, where the taper and diameter of the tool match that of the holder on the machine. That is why most of our products are standardized according to DIN 4000 and ISO 13396. We also participate in these standardization committees ourselves. Then the customer can assemble the desired parts as a digital twin and download them, including all dimensions. But that what does not exist without digital twin and platform: He can virtually install the parts in his machine and simulate their function. Anyone who orders something here is sure that it will work exactly as he needs it to.

Which manufacturers have you gathered on the platform?

Weigele: The Tool-Arena has been around since 2016, and we spun it off as a start-up. Now, 12 other brand-name manufacturers are offering their tools, clamping technology, measuring systems and more there with us. From Albrecht Präzisionsfutter to Hachenbach Präzisionswerkzeuge to Zoller, to pick out three according to the alphabet. You find them all on the platform under brands. All manufacturers in this environment are welcome and invited to us. The more that participate, the greater the value to customers, whether they are machine manufacturers or users. The Tool-Arena is a subsidiary of EWS Weigele, but our products can be found there on an equal footing with those of other manufacturers.

Business that would not exist without the platform

What business model are you pursuing with the Tool Arena?

Weigele: The principle is simple: Participation in the platform itself costs the manufacturer nothing. After all, they should benefit from it and sell more products. We are only involved with a commission if a sale is made via the Tool-Arena.

Have you already recouped your own investment in the platform with the resulting revenue? Is the tool arena worthwhile for you?

Weigele: The return on investment has not yet been achieved. It takes time for providers and users to accept the new model and for it to become established. But our investment has already paid off for two reasons: Someone would surely have set up an online marketplace like this sooner or later; we don’t have to wait for that now; we’re in it from the start. But more importantly, we had to get our own data in order. We had 3D models before, of course, and we had already digitalized many other steps in development and production. But not in a form that would have sufficed for a digital twin of the assembly with other components and the machines themselves. The platform customer would not have been able to do the functional simulation with our earlier data. In this respect, we are a big step further in our own organization than before.

Can you reveal something about the technical realization?

Weigele: We have some capable people on board who know IT and in turn know others who are experts in connecting, cloud and AI. Again, it was the network that mattered. We chose the Microsoft Azure platform as our technology foundation. But for the most part, we programmed the tool arena ourselves and with the help of external specialists. You can find out more details about the tools used from the platform’s managing directors, Andreas Jäger and Niklas Vogt.

What problems did you encounter with the platform? Were they more technical or of a different nature?

Weigele: The technical challenges are undoubtedly there and significant. The Din/ISO standards have their limits and do not reflect every technically important detail. The bigger stumbling block is certainly the still strong reluctance in the B2B industry market to address customers together with competitors and others. The idea of the platform economy simply goes against the usual thinking that my most important asset is my customer data and that the more tightly I keep that customer data to myself and serve those customers directly, the better my business will perform. But our partners see that there’s a new business developing here that they wouldn’t even be a part of in the traditional way. That’s why we are very confident that the idea was right and that the approach will prove successful.

Where do you see EWS Weigele and the Tool Arena in the future?

Weigele: We just received an award at the end of July from the network initiative “Alliance Industrie 4.0 Baden-Württemberg” as one of the “100 Places for Industrie 4.0 in Baden-Württemberg”. We are strongly anchored here in the region, but our customers and partners are not only in Germany. As the EWS Group, we already have locations in the USA and China, in Korea and Russia. The Tool Arena is bilingual and will certainly further strengthen our global presence. We believe that our future, like that of Germany as an industrial location, is global and digital. And believe it is important to be at the forefront of this.