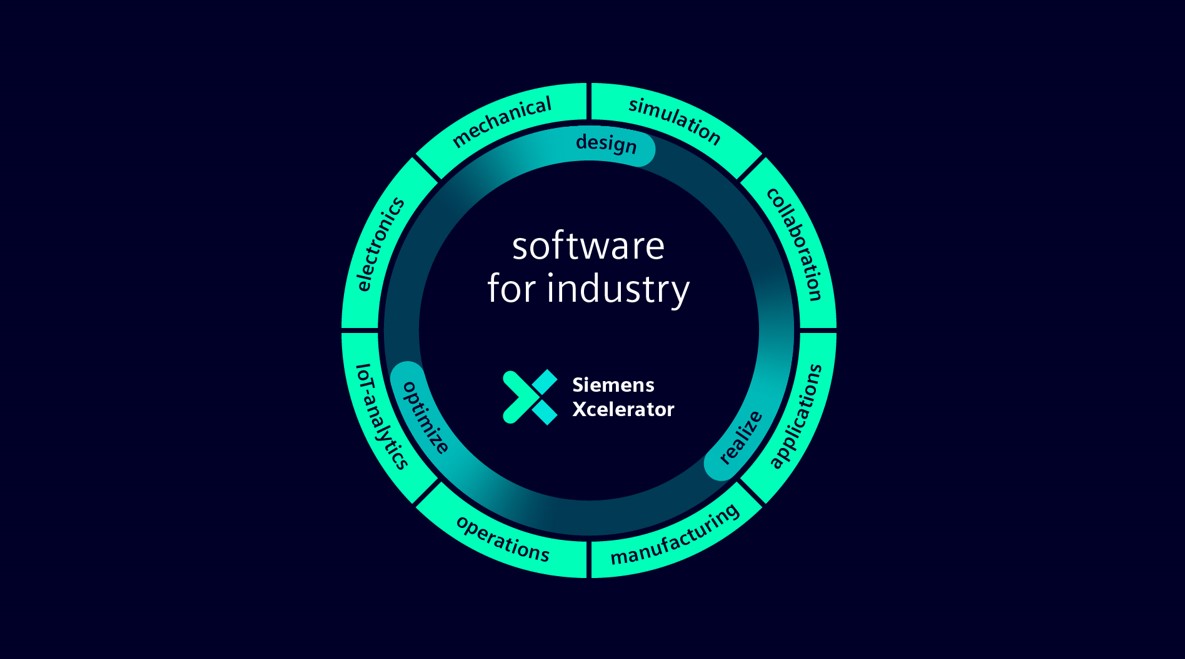

Siemens Digital Industries Software is one of the few vendors of industrial software, who covers the management of most of the core processes in discrete manufacturing and process industry. Like most software, in the past this has been monolithic software. In 2019, the company integrated their portfolio of engineering software, services, and application development platform as Xcelerator. Now, as part of its transformation into a technology company, Siemens AG is applying that same strategy across all parts of the business and expanded Siemens Xcelerator from a portfolio into a digital business platform for the entire company. Siemens AG announced and launched Siemens Xcelerator as an open digital business platform accelerating digital transformation, back in June last year.

Siemens is also the first – and may probably be the only one – of the well-known and for decades leading providers of industrial software, who decided to support this background series with an exclusive article about the positioning of Siemens and the new development to come in the next years. This alone is a good sign that Siemens will be also a powerful part of the new rising of software and services for the industry, that is to be seen everywhere: cloud native apps and services are offered by old and new companies and the industry itself, which is the long-awaited realization of the Industrial Internet of Things (IIoT).

Tobias Lange (Photo Lange)

Tobias Lange, Senior Vice President for the Manufacturing Operations Management (MOM) portfolio, mainly Opcenter, but also for Intra Plant Logistics for material management, the quality systems, which includes Teamcenter Quality, and Opcenter Intelligence, and Opcenter RDL for Formulation Design and Laboratory Management. In Digital Manufacturing, he is also responsible for technology and operations.

Scott Jones, Chief architect, now responsible for architecture and innovation within Digital Manufacturing segment, came to Siemens through an acquisition of the manufacturing software company Camstar in 2014, where he was the CTO. Scott has over 35 years of experience in the manufacturing technology.

Scott Jones (Photo Jones)

Starting In Manufacturing – But Aiming At Every Space

Ulrich Sendler: Mr. Lange and Mr. Jones, both of you belong to the digital manufacturing part of Siemens Digital Industries Software. Are container technology and cloud native services for Siemens only important in this application area?

Tobias Lange: No, we started there (as well as in other areas of the company), but we decided that this is something that is strategic for the whole company, and we do this not only for industrial software in the sense of PLM and MES and planning and scheduling or IoT, but we’re also doing this for everything, for virtual PLCs, for sensors on the shop floor, all the way to the top floor. This is the essence of Xcelerator. We do it, so that you can run a simulation model directly on an edge device, to improve the machine directly on the shop floor. This is why we took the really broad term Xcelerator to mean the future looking portfolio. And there is much more to come what we are going to launch especially at Hanover Fair 2023.

Ulrich Sendler: What is the current state of Siemens Software in the cloud? Which parts of your portfolio are already available as SaaS and on which platforms?

Tobias Lange: AWS is our SaaS vendor of choice when we run on public cloud. Most of our products are also certified to run on Azure and some also on Google Cloud. Pretty much everything you can have as SaaS operated environment. But that is only the first step. We take it forward to Xcelerator and that’s why you see an X when we launch products that are dedicated SaaS products like for example Teamcenter X. MindSphere is already completely on SaaS and now also offered for almost all the big cloud vendors, including Alibaba Cloud in China.

Now we leverage container technology in order to be a little bit more independent from the cloud vendors. Especially in terms of MOM we have a lot of customers from the consumer product goods space who wouldn’t accept anything that goes into an Amazon data center. So, we also partner up with Microsoft Azure. And here is the point where our cloud platform MindSphere comes in. In the past it was a separate offering, but with Xcelerator it has a very special role as part of Xcelerator Cloud, which is the underlying infrastructure to run any of our products in the cloud, services and applications with insight into the Industrial IoT space and connectivity from the sensors from PLC. MindSphere lets you gather that data either locally on an edge device and send it to a cloud or to your data lake and gain actionable insights. And now, this is integrated into our MOM offering, into our PLM and design offerings, and you close the loop and can really have a holistic data-driven manufacturing.

Ulrich Sendler: Would you say that MindSphere is kind of your enabler for hybrid cloud environments at your customer?

Tobias Lange: Yes, it’s in the middle of the different modes that we can run, a fully cloud enabled MES Solution integrates with MindSphere data but does also the same on all the different levels and is part of the Xcelerator Cloud environment. We tailor every industry and there are parts where it’s much more natural with the volume and the mix they are producing and the similarities between different factories to go into the cloud. And there are others like the semiconductor industry with a huge amount of throughput and data accumulated on the shop floor. I’m not sure if they will ever fully move their infrastructure to the cloud. We must support this in a hybrid fashion.

MindSphere (Image Siemens)

Ulrich Sendler: When did you start switching the software development to Container Technology?

Tobias Lange: Speaking for our MOM space I think it was six years ago that we started to have a closer look at this, and for about three years it is now the given direction with full steam ahead across our portfolio.

Open Software, Open Standards

Ulrich Sendler: Which standards are you relying on regarding container technology?

Tobias Lange: We heavily rely on Docker for containers, and for the orchestration of container clusters we utilize and support Kubernetes more and more. We are also supporting OpenShift if you use it as your Kubernetes environment. If you tie yourself into the complete ecosystem and infrastructure of it, that may help you avoid certain services. But I think that is creating a lot of vendor tie into a platform that potentially can be expensive. Besides these there are special standards for each platform that we support. And of course, also many other standards like OPC UA and MQTT …

Scott Jones: … not to forget the very important standards for authentication to make this open architecture safe for all partners involved.

Ulrich Sendler: How important are APIs for Siemens in the context of open software?

Tobias Lange: We believe in an open ecosystem. Siemens has the best-in-class solutions, but there might be special needs that we don’t fulfill, especially if you come into Brownfield deployments. There’s always a certain infrastructure that you need to tie into and see that through. It’s important that we treat our APIs as first-class citizens. At the same time, we recently launched the utilization of Mendix as a very comfortable way of building user interfaces for our Opcenter portfolio. We expose pretty much all of the business functionality, like Gartner is calling it packaged business capabilities, and with Mendix you can build your workflows and UIs around this.

Scott Jones: The API helps to get data in and out. That’s fine. But what binds it all together, what orchestrates it, what relieves work from the user? We as Siemens must take care of the semantic models and ontologies of the data, and then decide, what kind of technology we offer. In the semiconductor industry there are for example 4.000 pieces of equipment that they must communicate to in real time and need very quick and deterministic responses. How do I manage that in the cloud? That is one of the many examples where we are looking to maintain that hybrid approach.

Tobias Lange: We are here to deliver value to the end customer. How does my model behind this architecture look like? The customer doesn’t have to worry about it. His factory looks like this, and he expects the model to be the same across the PLC, across the IoT system, across the MES system. And he expects that the data flows between the different modules is something that the system just takes care of. We have to support a customer use case and we have to support it end to end.

Mendix Low-code Platform (Image Siemens)

Tobias Lange: The context is what we call closed loop manufacturing. You want to have data from the MES, the ERP and the PLM system and correlate some of this. With Mendix you don’t have to transfer all the data. The data comes from the systems directly live where you need it. And then you might have customizations modeled differently, where low code helps the users to access them. With Mendix Siemens can put software as modules in the library. Inside of Mendix studio there are objects in the library for your work order and your process model and you have the APIs available and start modeling your UI. And you can build your own applications easily to compliment the core portfolio, and it helps to maintain a “clean core” of the MOM/MES space as a system of record that makes upgrades much easier.

Ulrich Sendler: Is especially the younger generation emphasizing on low code?

Tobias Lange: Young people may find it a very natural way to use. But within our groups we have people that are close to retirement who started for the first time doing certain easy app development with Mendix, seeing that they suddenly understood how these things work out and that they were able to do it themselves rather than having to ask experts.

Ulrich Sendler: Does Siemens offer standardized ways for the integration of add-ons from customers? Or vice versa?

Tobias Lange: We are exploring this. We already had some offerings for putting apps in MindSphere, and also for Mendix we have such offerings. But I did not have any customers ask us to run their containers within our infrastructure. If you have the competency to build your own container infrastructure and containers, then most of the time you run your own infrastructure and want to get the Siemens software running in containers in conjunction with it. I think the bigger picture is really taking our software to the customer environment.

The Siemens DNA Is Set Up To Look Forward

Ulrich Sendler: I see a lot of companies coming up with composable software for the industry, especially around MES. Do you see them mainly as competitors? Or do you embrace them as partners?

Tobias Lange: I think it’s exciting to see the previously pretty closed up, but also very segmented scene, that was very focused towards specific industries, we and maybe two or three others actually being the ones that support most of the industries. But not seeing too much innovation for a number of years in the whole scene. Now there is a lot of movement, and we are excited about it, because we are set up in our DNA to look forward and say, there are things we can embrace and really take forward.

Some of the new players are coming more from the top. As you know we have strong partnerships. We partner with some big players coming from ERP in the PLM space, we partner with their ERP, but in the manufacturing space this is also competition. It’s an opportunity for us, because we are the only ones that actually live from the sensor up to the top floor, that can move software between all of those stacks because we know by heart where we are at and what this actually means in these different domains. And some of the new players come from the bottom, they maybe don’t understand what it actually means to run in the PLM space. While the ones from the top don’t really understand the shop floor requirements.

On the other side there is really technology and disruption, and I think you either eat or you get eaten. You have to embrace the new technology and that’s what I tell our team all the time. And we’re innovating pretty quickly and driving and embracing these things forward. We are at a good position, we are excited about the change and the new possibilities, but we need to stay humble and see what is out there in the market and give our answers.

Ulrich Sendler: In which scale categories of industry do you see a trend to container technology? I have the impression that it is either the big groups or the small start-ups.

Tobias Lange: I think your assessment is absolutely correct. This is sort of the space where we get questions around this. I wouldn’t say that it’s not important for the others. But most of the companies just want to have a solution for Zero downtime, easy upgrades, easy customization, lower cost of ownership. They don’t care about the database system and don’t need a container solution. But our answer to that is a container solution, because it’s the most pragmatic approach to that.

Tobias Lange: There’s not any area that we’re not actively looking or pursuing or also having already launched some solutions. If you look at the Industrial Edge ecosystem, that’s solely based on containers, so basically anything in this environment is directly being impacted and run with container infrastructure, the whole MOM space is definitely there.

If you look at the traditional PLM software, this is something that is getting explored more and we have to look at details. Overall, we want to have an Xcelerator based infrastructure including containers also for all our software. Containers provide a lot of the capabilities that we offer already, for example with Teamcenter X.

Xcelerator (Image Siemens)

Ulrich Sendler: For more than ten years Industrie 4.0 was a big promise that did not really come to work. Is container technology the medicine that can help?

Tobias Lange: A lot of times, the whole industry puts out these statements and then nobody looks at them anymore. A lot of the promises from the past regarding a mechanical model and directly generating the code for your robot or your code for your PLC out of that mechanical model, and now with some of the technologies that we are having there, it’s getting much easier done. I think there’s also a lot of paradigm shifts around this and the notion of seeing that you have multidisciplinary work, where people start collaborating, that the walls between IT and OT break down and not only IT and OT, it’s also the walls between product design, product engineering and manufacturing, where we are seeing this getting much easier, if you have these kind of paradigms behind it that we talked about today.