On May 8 at the Holiday Inn Frankfurt Airport, no less than three speakers took the stage at the 58th meeting of the sendlercircle: Sharam Dadashnia, Chief Data Scientist at Scheer PAS; Christian Stein, CEO of Threedy; and Plamen Kiradjiew, Head of Solution Architects at German Edge Cloud. The umbrella topic this time was: Composable Software as a major challenge and opportunity for the digitalization of industry. And this topic was examined from three very different perspectives.

Sharam Dadashnia, Chief Data Scientist at Scheer PAS (Photo Sendler)

Sharam Dadashnia, who in addition to his role as Chief Data Scientist at Scheer PAS also wears the hat for Product Management & Marketing, made the start. Scheer PAS is the youngest subsidiary of the Scheer Group.

Prof. August Wilhelm Scheer started his long career as a teacher, researcher and company director back in the 1980s.

And he did so with the famous Y, which since then has symbolized the need for software-based integration of order fulfillment processes with those of engineering for effective production and good customer service.

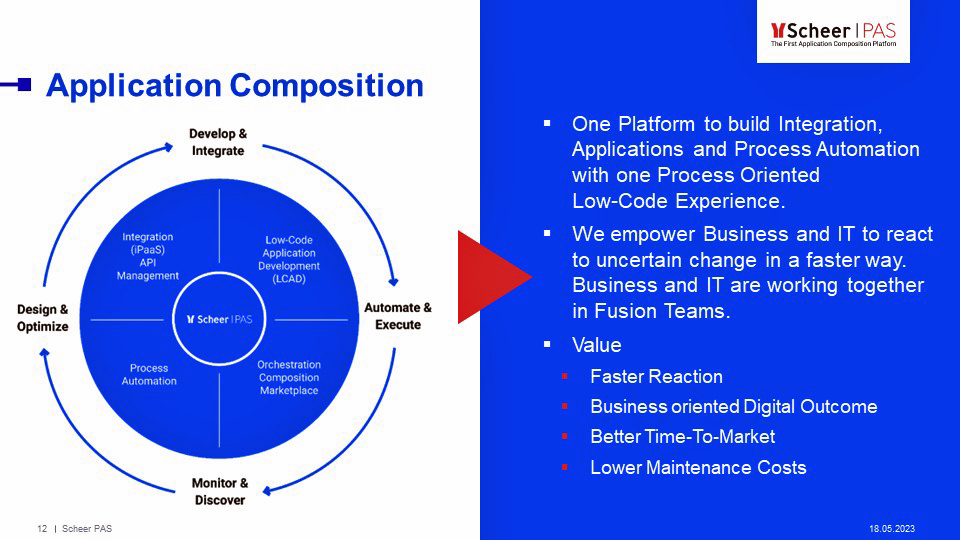

Scheer PAS: Application Composition and API Management

According to Sharam Dadashnia, Scheer PAS supports companies in “Application Composition”, because the future is seen in apps and services that communicate and function well with each other. Since the data exchange required for this is increasingly to be regulated via APIs, Scheer PAS offers a platform as a service with which API management can be automated. Including a low-code platform especially for the easy design of the user interface.

The reason for the company foundation and the solution approach is the assumption that in the digital enterprise world a fast “Managing Change” and the very fast adaptation and repeatedly realized reorganization of the business, in short agility and adaptability, become the central requirements.

It is precisely this speed and dynamism in the entire business activity that can only be achieved through the orchestration of many small, easily assembled software components, so-called “Composable Applications”. Scheer PAS thus follows the 2020 study published by Gartner, which sees the companies of the future as a “Composable Enterprise”, itself composed of numerous small modules and units, which only require the large corporate umbrella for the common and economical use of central resources.

Gartner has coined the term Packaged Business Capabilities (PBC) for these composable applications. In corresponding architectures, such PCBs are increasingly also found as components or functions of monolithic systems – as they have been used almost exclusively in the past – alongside new, small modules developed from the outset as cloud-native software for interaction on a platform as container apps.

The discussion with the participants of the sendlercircle led to a deepening of the topic, what has to be done and observed fundamentally by the industrial companies and what by the IT providers, if such architectures and infrastructures are the goal. The challenges associated with such conversions of industrial IT were also discussed very openly. Because even if they ultimately ensure greater agility and adaptability, they still require a new way of thinking and a different approach to development, deployment and maintenance than IT departments have known up to now.

Scheer PAS has been a strategic partner of the Friedhelm Loh Group since last year and works closely with its subsidiary German Edge Cloud.

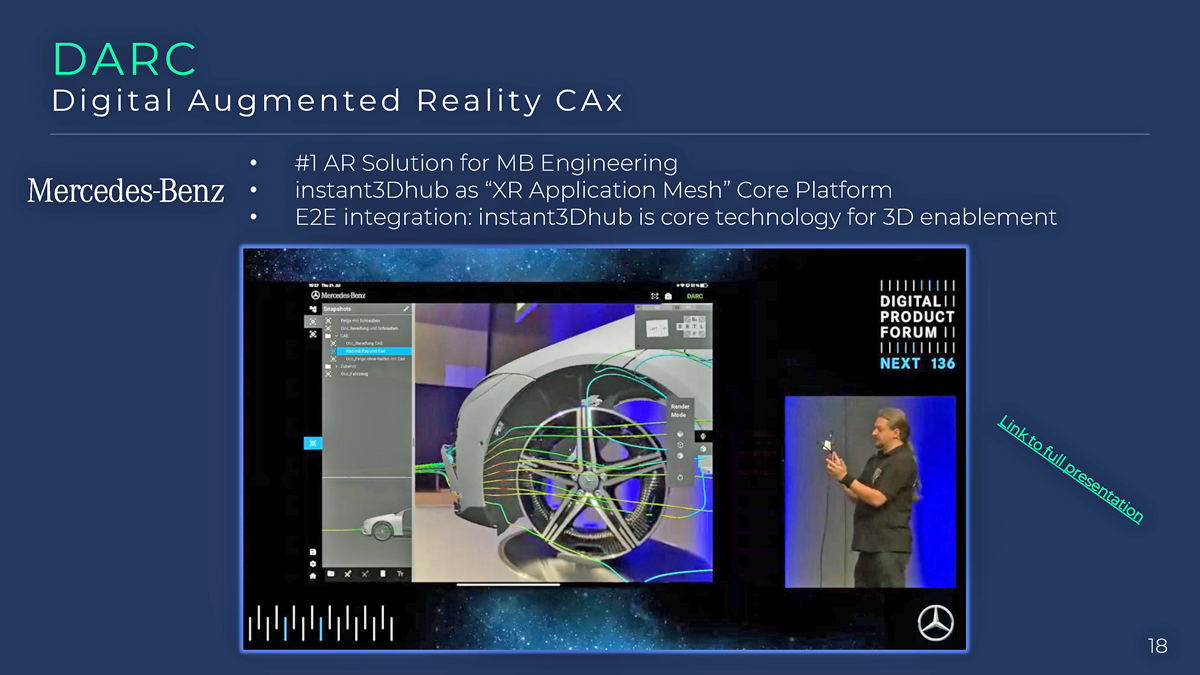

Threedy: Rethink Industrial 3D

Threedy is a spin-off of Fraunhofer IGD in Darmstadt. Managing Director Christian Stein explained the approach of the Instant3Dhub product, which is already being used by a group of well-known companies from BMW and Porsche to Siemens and Trumpf: Instant3Dhub is designed to help industry leave behind the bottlenecks of data conversion, 3D file boundaries, and client-server computing in their increased use of increasingly complex digital twins from different sources throughout the product lifecycle.

With instant3Dhub Threedy integrates computer graphics, cloud and service technologies in the form of a highly scalable software-as-a-service platform, which can of course be implemented not only via cloud solutions of any kind, but also on site.

algorithms are automatically distributed based on the devices involved to perform calculations on the 3D data as quickly as possible.

Christian Stein, Managing Director of Threedy (Photo Stein)

The user sees the 3D data on his end device in original resolution, as if he had downloaded the entire 3D model. In reality, however, only the necessary data fragments are transferred without any conversion being necessary.

Threedy sees web technology as the predominant technology platform on which all applications will communicate and collaborate in the future. According to Christian Stein, this is the only way to achieve the 3D omnipresence demanded by the industry. Not with the existing and so far mostly used closed systems and the high effort that is unavoidable with the 3D data usage.

The industry’s need to be able to use product data along the entire product life cycle for a wide variety of purposes relates in a special way to the three-dimensional digital twin. Processes should be better supported as a result. So the processes also need to be able to quickly deliver and receive the necessary data. This is what the concept of Threedy serves. It is directly opposed to the application- or even document-driven and with manual effort burdened conventional 3D processing.

Threedy’s partners already include companies such as Siemens, 4soft and :em engineering methods. With Microsoft, the integration of Instant3Dhub into MS Teams has just been introduced. Threedy’s claim is to offer something like “Google Maps for 3D Data” with its 3D streaming services.

German Edge Cloud (GEC): Composable IT for the factory – a concrete example

Plamen Kiradjiew spent many years at IBM, where he was most recently involved with AI for industrial applications. Now he is Director Solution Architects at German Edge Cloud. He presented a demo case that he created with a team of experts from the sister companies Eplan, Cideon, GEC and Rittal. This is a concrete example from their own company, which shows the ONCITE Digital Production System (DPS), launched last year, in practice on the basis of three digital twins.

Plamen Kiradjiew, German Edge Cloud (Photo Sendler)

The example follows the individual steps of manufacturing the control cabinet as a component of the Perforex MT machining center used for production.

The mechanical data is transferred as a digital product twin from the mCAD or PDM system directly to Eplan via Cideon Conify. There, the engineering of the integrated control cabinet takes place as a digital plant twin.

As a result, the data of all control cabinet components ends up as a bill of materials in the ONCITE DPS, the digital manufacturing twin.

This digital production system is based on a Kubernetes cloud infrastructure and includes an ONCITE Industrial Suite consisting of several software service modules that not only enable production control, but also continuous monitoring with the help of a virtual factory dashboard. The special feature compared to hard-coded production control systems is the fast and, above all, simple adaptability during operation.

In the demo, a part with an incorrect part number had been placed in the production workflow and could not be loaded because the system could not find a bill of materials for it. With easy inputs, the fields of the manufacturing order were made editable, the part number was corrected, the order was resaved and successfully uploaded.

The second part of the demo was even closer to the shop floor: Via low-code, the visualization of the production was adjusted with a few clicks to show not only the operating status but also the current energy consumption and the speed of the milling cutter. Visibly increasing the effectiveness of data use without specialized IT knowledge – that’s what Composable Software allows in the factory. Plamen Kiradjiew even gave the participants a direct live insight into the control cabinet production at Rittal in Schwaiger at the end. There, the ONCITE DPS has been introduced. Currently, the rollout is running in 12 factories.

The benefit of the debates in the sendler\circle

The sendler\circle has been a community of interest for software and service providers in the industry since 1995. It continuously deals with technologically significant developments and trends that are important for the manufacturing and process industry. With a special focus on the particular situation in the industrial location of the German-speaking countries.

The number of suppliers represented is currently less than ten. For participants and speakers alike, this has the very positive effect that discussions take place here that are otherwise only possible in small and very specialized working groups. Here they run on a high strategic level. The sendlercircle is pleased about new members interested in such exchange.

The current members of the sendlercircle are: Achim Rossel, Senior Vice President Business Development, DSC Software AG; Wolfgang Dietzler, Managing Director ECS, Dieter Pesch, Senior Vice President Development and Product Management, Eplan; Thomas Gilgenberg, Managing Director ICP Solutions; Tim Weilkiens, Managing Director oose Innovative Informatik; Dr. Karsten Theis, Member of the Board PROSTEP AG; Dirk Kremer, Enterprise Integration, Siemens Industry Software.