Embedded In Microsoft Dynamics Finance & Supply Chain Management

During the past years the number of PLM vendors was continuously shrinking. Especially in Germany and the German speaking region there is not much local software left. With Bluestar PLM there is a new name now, though the software is already on the market for more than 20 years. It is coming from Aalborg in Denmark, where the developing company PDM technology Group ApS has its headquarter. 2023, Bluestar PLM was for the first time shown on the Hanover Fair. PDM technology Deutschland is located in Handewitt near Flensburg.

Bluestar PLM is not like most of the other PLM systems. It is fully embedded into Microsoft Dynamics F & SCM, which is the latest name for the Microsoft ERP software. Bluestar PLM is written in the language of this ERP software, functioning as a module of this software, and this was true from the beginning. I was able to have an interesting talk with Dr. Jørgen Schiønning Larsen, who founded PDM technology and is CEO of the Group.

Interview with Dr. Jørgen Schiønning

Ulrich Sendler: Dr. Schiønning, when you founded PDM technology in 2001, you were already looking back at more than ten years of industrial software development and consulting all around CAD/CAM in engineering and production. What was the initial idea for the new start?

Jørgen Schiønning: Two thoughts were there at the beginning. First, engineers must have a PLM solution to be able to access all the product data they need over the whole product lifecycle. And second, which turned out to be even more critical, PLM must be very closely connected with ERP.

As a toolmaker and mechanical engineer, I had worked mainly in and for companies in the Engineer to Order business. Grundfos was one of them, where we started with some CAD/CAM software development based on Computervision in the early Eighties. With our software we could automatically generate the drawings and the machine code for manufacturing by parametric.

Dr. Jørgen Schiønning Larsen, founder and CEO of PDM technology (Photo PDM technology)

That was simply at the edge of the industry at that time. And then for ten years my own company developed and delivered software with a focus on getting plot-files from CAD-systems displayed on PCs fast. We were working for several big shipyards and their suppliers, which is a very typical industry for Engineer to Order. No ship is like any other, but the re-use of parts and components is crucial.

Ulrich Sendler: What makes the big difference in engineering?

Jørgen Schiønning: Engineer to Order is quite different to the work of a typical design engineer who shapes the product from the idea to the manufacturing release, what he can almost do solely with CAD and PLM. In the Engineer to Order business on the other hand, you start with existing products, components, and parts, while in parallel discussing with the customer about his concrete needs for the new order, the time to deliver and the pricing. And synchronously you start to talk to suppliers and other partners. That is why you need both, PLM, and ERP, from the very start. And that is why we developed our Bluestar PLM in the late Nineties within the ERP software called Axapta from NavisionDamgaard, on which one of our important customers had his company running.

For more than 20 years Bluestar PLM has been ERP-embedded (graphic PDM technology).

Embedded for more than 20 years

Ulrich Sendler: That was before the acquisition of NavisionDamgaard by Microsoft?

Jørgen Schiønning: Exactly. When Microsoft made Axapta the ERP part of its platform in 2002, we were already embedded and running as a module of Axapta 3.0.

Ulrich Sendler: How did the industry react to this offer? I know that many engineers all over the world and especially in Germany don’t like ERP to be ‘first’. They want engineering software to play in the first row.

Jørgen Schiønning: In the industries that we were addressing, this was not so much the question. But the companies simply could not imagine that it was possible to have PLM being embedded in ERP. Another hinderance for us was the fact that almost every company at that time made the decisions for ERP and PLM separate from each other.

With the well-known problem at the end of having two different monolithic software tools that need a lot of effort to convert data from one to the other and can not easily be used for cooperation between the different departments. We had to show them that our solution was working well.

Ulrich Sendler: Since you are in the market for more than 20 years and now even entering new regions, you seem to have been successful in convincing your customers. How did you grow?

Jørgen Schiønning: To be partnering with Microsoft turned out o be a very good starting point. US companies are usually thinking more globally. So, they did not see a Danish provider as strange, and they took the platform of Microsoft and our software being embedded in ERP as a benefit, looking at their global footprint and many production sites all over the world. We grew about 25% per year. But not in the German speaking areas. Today we make about 60% of our business with US companies, and they represent a big part of our customer base. For many years we had to accept that the European and especially the German market were difficult for us.

Ulrich Sendler: What was it that let you address the industry location Germany again?

“The pandemic has changed the whole situation”

Jørgen Schiønning: The pandemic changed the whole situation. People were working at home and needed modern, Internet-based solutions. They wanted to have any important data accessible via ERP from home. Pre-defined data through one-on-one interfaces was not enough anymore. And how could they work with secure connections between different software tools? Also, Industrie 4.0 and the Industrial Internet of Things were pushing in the same direction. Companies began to have a new look at the Microsoft platform. We began to show our solution successfully to German customers. And, by the way, our growth went up to more than 30% in the first year of Corona, and last year it was at about 50%.

Ulrich Sendler: Microsoft is not the market leader in ERP. Was your decision for that platform the right one?

Jørgen Schiønning: You are right, Microsoft may only have 5% of the ERP market share. But it is a platform, widely used and global, that is supporting our solution. And being embedded in their ERP is our unique selling point. Everybody is talking about the single source of truth for many years.

We can offer that. There is no better kind of connection between ERP and PLM. Our PLM is part of ERP. The user does not even have to realize, that he is switching from a PLM function to an ERP function. He is just doing his work.

Bluestar PLM follows the structure of the customer’s process. Not the other way round, where he must change his processes so that they fit to his software.

Bluestar PLM shows well connected (graphic PDM technology)

Ulrich Sendler: How difficult is the implementation of Bluestar PLM? And how easy is customization? Because PLM users normally try to optimize the engineering software.

Simple and fast, out of the box

Jørgen Schiønning: Here we come to some more benefits of our solution. A normal midsize company doesn’t need more than 75 days of our consulting, to have the software running. Maybe a hundred days. But that’s it. And it is running out of the box. They don’t need to customize it anyhow. Of course, they can. But usually, they only add some fields for specific data. They don’t change the functionality. Because it is not necessary. And there is no interface for data exchange to ERP that they must be concerned about.

Bluestar PLM in use (Photo PDM technology)

Ulrich Sendler: What about connecting to different CAD/CAM solutions? How does Bluestar PLM support the digital twin?

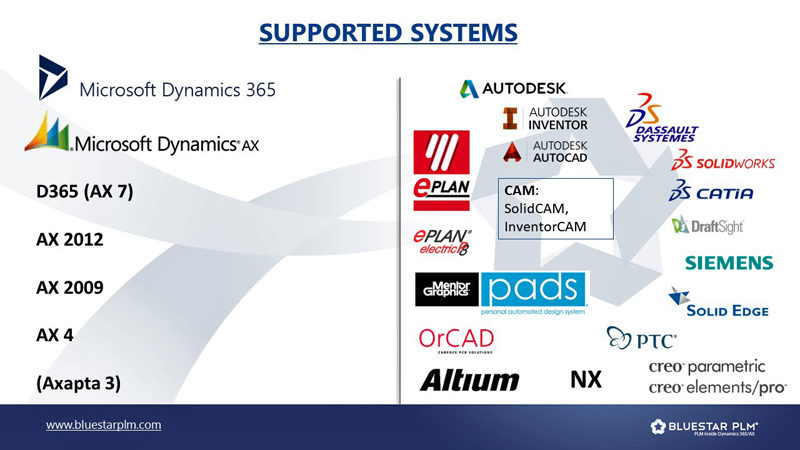

Jørgen Schiønning: We support all the modern CAD/CAM systems like SolidWorks, Solid Edge, and Inventor, which have modern APIs. With our 3D-CAD integration module you can configure the product very easily

Ulrich Sendler: Which kind of industry company is your typical customer? Is it more the small and medium businesses?

Jørgen Schiønning: No, we have companies of all sizes, from 5 engineering seats to 1.000 seats at 50 sites worldwide. Our typical customer is in the Engineer to Order business, and he normally has a big number of product variants. It is this kind of companies that are looking for a Microsoft Azure based solution. They believe in that platform and know that this kind of software is running on all their computers. In total we have about 125 customers with more than 50.000 seats across the globe.

Ulrich Sendler: What about the role of PLM: Will it still be important as technical backbone? What do you think will be the role of PLM in the future?

Jørgen Schiønning: We are convinced that the importance of PLM for the industry will further grow. But crucial will be the tightness of the connection to ERP and all the other IT implemented. That’s why we are very much looking forward to the developing market of the coming years. People understand more and more the benefits of working on one platform. And we are there with two decades of experience.

Ulrich Sendler: Let me ask you one final question: What can we expect next from PDM technology? Is there anything interesting in the quiver, that you can talk about?

Jørgen Schiønning: Yes. We are excited to have a prototype running which also uses the Microsoft Azure IoT platform. So, if a machine builder inserts a sensor into his machine, this machine type will show his sensor list to the customer, so that he is able to manage the device status with Microsoft Dynamics 365 Connected field service. Having behind it the 3D CAD model of the machine, the device, the sensor, using it as the digital twin.

We are entering the European market just at the right time. With more and more functionality for manufacturing and process industries to come.