pragmatic way to establish System Lifecycle Management (SysLM)

Technische Universität Kaiserslautern

Lehrstuhl für Virtuelle Produktentwicklung

The complexity of Product Lifecycle Management (PLM) implementations has already reached an unpleasantly high level, and the rise of complexity of products and their development will probably accelerate further. By establishing System Lifecycle Management (SysLM) as the next level PLM this complexity including all benefits and disadvantages becomes even higher. While integrating the whole topic in one huge PLM or SysLM solution is one possible approach, the exact opposite of an all-in-one solution is a fully modularized approach which leaves the corporate IT including its best-of-breed systems untouched.

If you consider the best-of-breed version as a valid alternative, then the following approach might provide a pragmatic way to introduce SysLM into the corporate IT environment.

The What

In Figure 1 an exemplary data flow for a typical PLM environment is shown. Data is generated in an authoring system like a Mechanical Computer Aided Design (M-CAD) tool and administrated in an appropriate Team Data Management (TDM) system. All those software tools are left untouched when the Engineering Bill of Material (E-BOM) is exported from the TDM in a neutral format. In this case STEP AP242 XML is chosen to export the product structure to the PLM Backbone.

With “STEP AP242 edition 1 – managed model-Based 3D Engineering” the two leading STEP Application Protocols (AP203 and AP214) are merged to further increase the quality of data exchange in the area of mechanical design. The format is currently being standardized by the ISO and contains a business object model which represents non-geometric functionality to support PDM interoperability. An XML schema is derived from this business object model to allow for an exchange of product structure information based on STEP AP242 XML. See http://www.ap242.org/ for details.

Figure 1: Data flow of PDM product structure from M-CAD to PLM Backbone (STEP AP242 XML)

The Why

System Lifecycle Management gives the opportunity to manage corporate wide processes in one place by utilizing a PLM Backbone as repository for all process relevant data. Figure 2 illustrates how the concept fits into a modern and model based IT architecture without disturbing established software and process infrastructures.

Figure 2: The role of neutral data interfaces (STEP AP242 XML, ReqIF etc.) for SysLM

The PLM Backbone can be connected to the corporate IT through neutral data interfaces which leaves total freedom of choice regarding the actual software products. Flexibility and modularization for any kind of corporate IT components is supported and allows for best-of-breed solutions as required. Processes can remain at their original place or advance to the SysLM level where they can be performed and their results are propagated down to the responsible corporate IT systems.

The How

To exchange the product structure of an E-BOM in a standardized way it has to be extracted from the respective TDM and relevant items have to be mapped to a standardized data model. Prototypes for PTC Windchill and Aras Innovator show great promise for further development in this area.

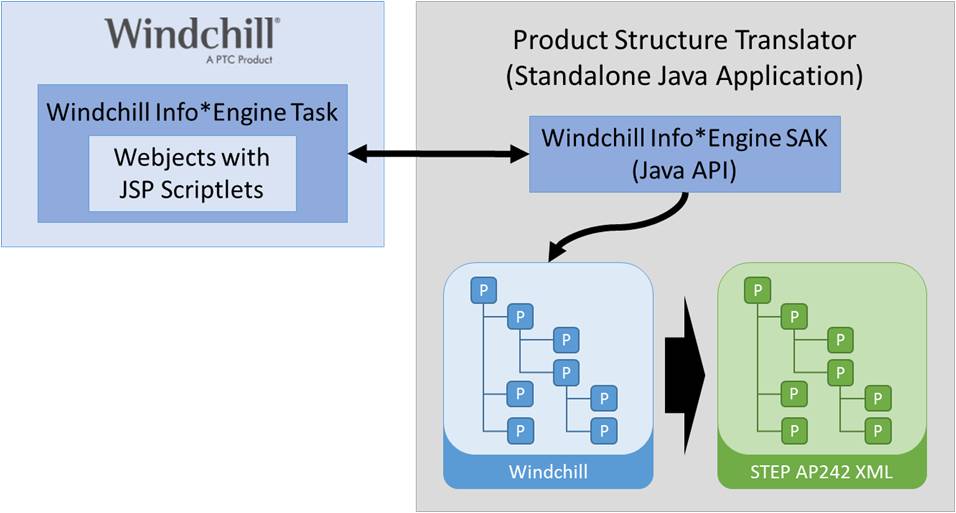

The prototype for PTC Windchill (see Figure 3) extracts a product structure on the Windchill server through a task in the internal Windchill Info*Engine. This task, which consists of a webject with JSP scriptlets, is placed on the server side and creates a Windchill conform product structure for a given assembly. This task can be invoked from a stand-alone Java application based on the Windchill Info*Engine SAK (Server Access Kit) to retrieve the assembly. The translator then maps the Windchill data model to the STEP AP242 XML data model and generates an XML file. Since the translator itself is a standalone application it could be executed right on the Windchill server or on a remotely connected client computer as depicted in Figure 3.

Figure 3: Product Structure Translator from PTC Windchill to STEP AP242 XML

For Aras Innovator there is a similar prototype to extract a STEP AP242 XML (see Figure 4). Aras Innovator provides access to its server via the Adaptive Markup Language (AML) which can be used locally or from a remotely connected client. The translator is a standalone C# application which uses the Innovator Object Model (IOM) API in .NET to communicate with the server. Unlike PTC Windchill, Aras Innovator does not use artifacts (like tasks) previously placed on the server. All functionality is integrated in AML and can be invoked directly through the IOM API. Similar to PTC Windchill the exported data model has to be mapped to the STEP AP242 XML data model before generating the XML file.

Figure 4: Product Structure Translator from Aras Innovator to STEP AP242 XML

For the actual mapping between the different data models best practices are currently being evolved by an independent committee to ensure compatibility. In a further stage a STEP AP242 XML export function might be natively integrated in relevant software solutions which is a common development for ISO standardized data formats.

Contact

Prof. Dr.-Ing. Martin Eigner

Dipl.-Wirtsch.-Inf. Sebastian Sindermann

Technische Universität Kaiserslautern

Lehrstuhl für Virtuelle Produktentwicklung

Gottlieb-Daimler-Straße 44

67663 Kaiserslautern

https://vpe.mv.uni-kl.de