Industry is expected to deliver individualized products as quickly and cheaply as mass-produced goods. However, many companies do not have the one digital twin of their products that enables automation of handling across processes. They have a CAD model in design, a PDM model for reusability, production and maintenance, and perhaps a configurator for sales. Cideon Conify now helps to make the data chain continuous.

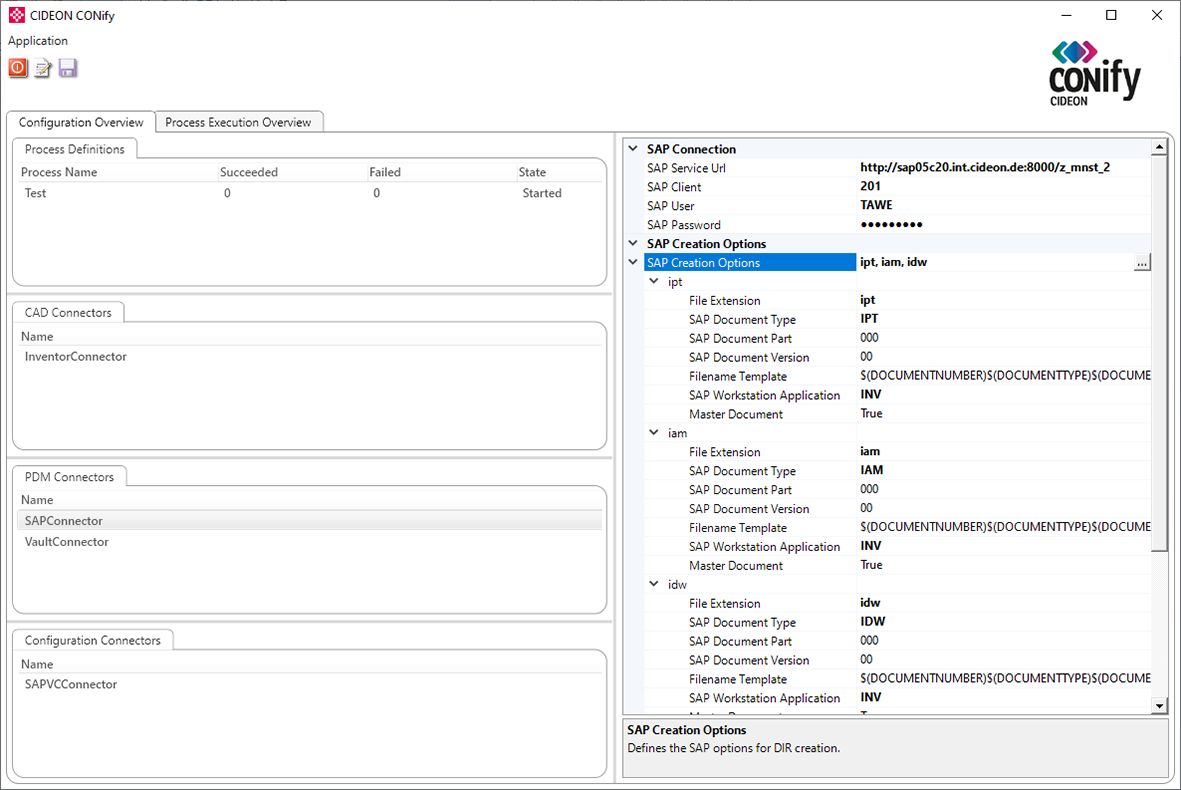

Cideon Conify supports the processing of quotations and orders for products with many variants. The new solution pulls product data from the CAD system (initially supported Autodesk Inventor and Solidworks), stores it in the PDM system (initially supported Autodesk Vault and SAP ECTR), and makes it available to sales configurators such as SAP or Autodesk FDU (Factory Design Utilities) in an automated manner. This allows the data flow to be continuous and automates order processing as if the data were in a single system.

This gives order design the ability to capture customizations with minimal additional effort. Order processing and manufacturing work with clear and consistent documentation, bills of materials, and routings. The result is a standardized, digital process from quotation to delivery with the highest possible level of automation.

Sales can create convincing offers that are enriched by visualizations, drawings and CAD models. Cideon Conify automatically generates CAD-neutral product data based on the available parametric CAD data – usually in simplified overview form. In the event of an order being placed, it then becomes more precise. When the order is created, the parametric data can be used to generate detailed product assemblies, enabling complete, variant-specific creation of part masters and bills of materials; while maintaining accurate reuse of historical parts and assemblies.

Cideon Conify is modular in design, with provision for the connection of additional systems through connectors.